3D Bioprinter for Applications in Tissue Engineering

In this project, I designed and built a 3D bioprinter for fabricating artificial skin tissues to promote and accelerate wound healing in diabetes patients. The artificial skin tissues are 3D constructs of collagen protein embedded with fibroblast cells. Thin layers of collagen are deposited on a temperature-controlled platform along with fibroblast cells between each layer. I worked in close collaboration with a chemist and a biologist to optimize the collagen formulation.

Design and hardware integration

This device uses a motorized syringe and a custom-built syringe pump capable of dispensing volumes as small as 100 nl of collagen and cells. The spatial resolution of the 3D printer is driven by the inner diameter of the dispensing needle. This printer integrates stepper motors, motorized linear rails, a motorized syringe and a custom-built syringe pump, which are all connected to a Galil motion controller and interfaced with LabView. The custom-built syringe pump allows depositing uncross-linked collagen on the temperature-controlled platform while the motorized syringe seeds cells between the collagen layers. The temperature-controlled platform allows controlling the cross-linking process of the collagen constructs.

Testing the optimized the collagen formulation. A full layer of collagen was first deposited. The second layer features gaps for cells to fill.

Testing the optimized the collagen formulation. A full layer of collagen was first deposited. The second layer features gaps for cells to fill.

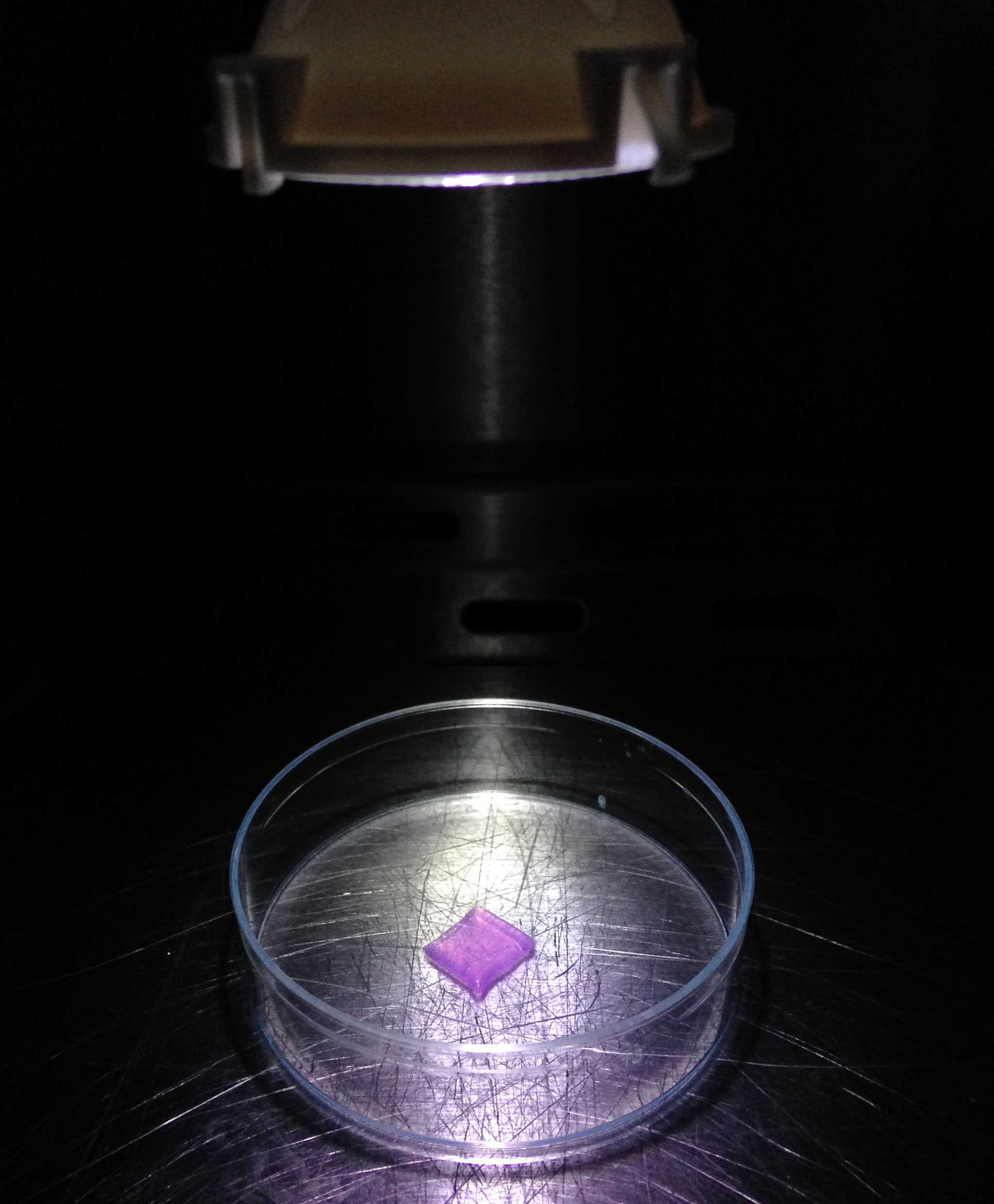

The construct is exposed to a low-energy UV light to create covalent bonds between the collagen fibers and keep the cells viable.

The construct is exposed to a low-energy UV light to create covalent bonds between the collagen fibers and keep the cells viable.